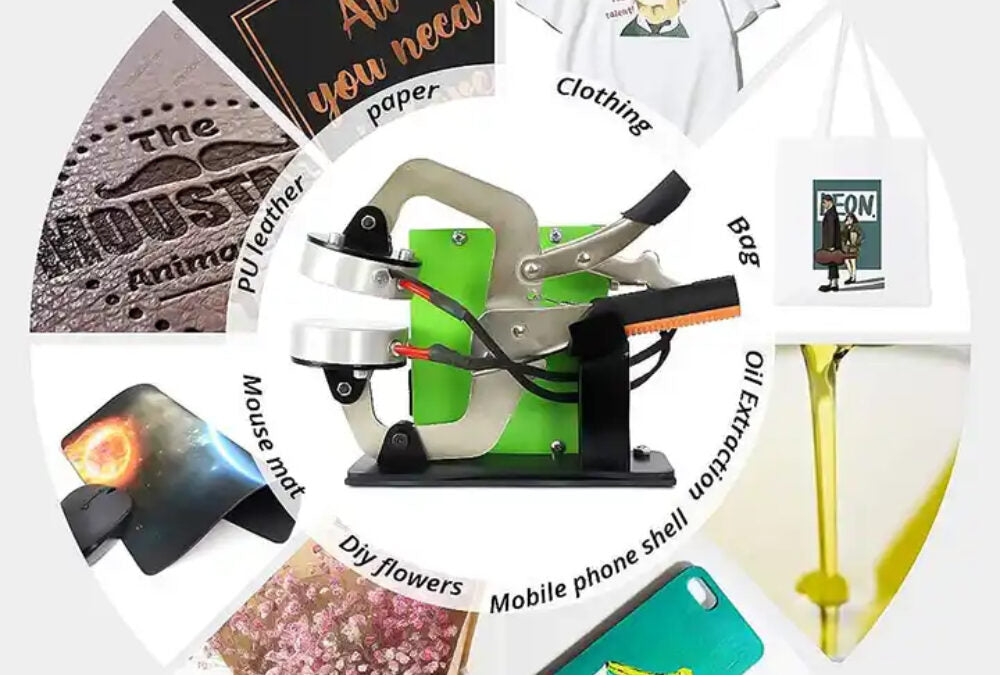

Suprising Uses for a Rosin Press

Share

Cold pressing?

What is cold pressing?

Cold pressing, also known as cold extraction or cold-pressed extraction, is a method of obtaining oils or juices from various plant materials without the use of added heat. This extraction process is employed to preserve the natural flavours, colours, and nutritional components of the extracted substance. The term “cold pressing” refers to the fact that the temperature during the extraction process is kept relatively low, typically below 120°F (49°C), and sometimes even lower.

The cold pressing process usually involves using a hydraulic press or screw press to apply pressure to the plant material, such as seeds, nuts, or fruits. The pressure helps release the oils or juices from the plant cells, and the extracted liquid is then collected. Unlike traditional methods that involve heat, cold pressing aims to minimize the degradation of sensitive compounds, such as volatile oils, enzymes, and nutrients, which may be altered or destroyed at higher temperatures.

Cold pressing is commonly used for the extraction of oils from various seeds, nuts, and fruits, resulting in oils that are considered more flavourful and nutrient-rich compared to those obtained through processes involving higher temperatures. Olive oil, coconut oil, and almond oil are examples of oils that are often cold-pressed.

In addition to its use in oil extraction, the term “cold pressing” is also used in the context of juice extraction, particularly for fruit and vegetable juices. Cold-pressed juices are made without pasteurization or high-heat processing, aiming to retain the fresh taste and nutritional content of the raw ingredients.

Can I cold Press with a Rosin Press?

A rosin press with the heat turned off, or down low, can be used for cold pressing to some extent, but it may not be as efficient as a press specifically designed for cold extraction. The primary purpose of a rosin press is to apply both heat and pressure to extract resinous compounds from cannabis or hemp material. Without heat, you lose the benefits of temperature-related changes that make certain substances more pliable and easier to extract.

If you turn off the heat on a rosin press and use only pressure, you can still exert force on the material, but the efficiency of the extraction may be reduced, and the consistency of the output may differ from what you would achieve with a dedicated cold press. Ideally you would need a hydraulic rosin press for cold pressing.

For optimal cold pressing, it’s recommended to use equipment specifically designed for this purpose. Cold presses for oil extraction are designed to operate without the addition of heat, preserving the delicate flavours and nutritional components of the oil.

If you’re attempting cold pressing with a rosin press, you might need to experiment with pressure settings, pressing time, and other variables to achieve the desired results. Keep in mind that the effectiveness of this approach can vary based on the type of material you are pressing.

Always be cautious when modifying equipment, and make sure that the chosen method aligns with the characteristics of the material you are working with. If cold pressing is a primary goal, consider using equipment designed specifically for cold extraction to ensure better efficiency and results.

Ideal for cold pressing

What Can I Try to Cold Press?

Cold pressing is a method of extracting oils from various plant materials without the use of added heat. This extraction process helps preserve the natural flavours, colours, and nutritional components of the oils. Some common cold-pressed plant extracts include:

-

Olive Oil:

- One of the most well-known cold-pressed oils, olive oil is extracted from olives using a hydraulic press. Cold pressing helps retain the distinctive flavours and nutritional qualities of the oil.

-

Coconut Oil:

- Cold-pressed coconut oil is obtained from the meat of coconuts. This process helps preserve the coconut oil’s natural aroma and flavour.

-

Avocado Oil:

- Avocado oil is extracted from the flesh of avocados using cold pressing. This method helps retain the rich, green colour and the characteristic flavour of avocados.

-

Almond Oil:

- Cold-pressed almond oil is obtained from raw almonds. This method preserves the nutty flavour and nutritional content of the almonds.

-

Flaxseed Oil:

- Flaxseed oil is cold-pressed from flaxseeds, and this method helps preserve the oil’s omega-3 fatty acids and other nutritional components.

-

Grapeseed Oil:

- Grapeseed oil is often cold-pressed from the seeds of grapes. Cold pressing helps retain the light flavour and potential health benefits of the oil.

-

Sunflower Oil:

- Cold-pressed sunflower oil is obtained from sunflower seeds. This method helps preserve the oil’s mild flavour and nutritional properties.

-

Sesame Oil:

- Sesame oil is extracted from sesame seeds using cold pressing. This method helps retain the characteristic nutty flavour of the oil.

-

Pumpkin Seed Oil:

- Pumpkin seed oil is cold-pressed from pumpkin seeds, preserving its dark green colour and the unique nutty flavour.

-

Hemp Seed Oil:

- Cold-pressed hemp seed oil is obtained from the seeds of the hemp plant. This method helps preserve the oil’s nutty flavour and nutritional profile.

These cold-pressed plant extracts are commonly used in culinary applications, skincare products, and dietary supplements due to their natural flavours and nutritional benefits. Keep in mind that the quality of cold-pressed oils can vary, so it’s important to choose high-quality, unrefined options for the best results.

Can I Use a Rosin Press For Embossing leather?

While a rosin press is not designed for printing in the traditional sense, some users have experimented with adapting rosin presses for heat-embossing or debossing on leather. The heat and pressure capabilities of a rosin press can be used to create impressions on leather surfaces. This method is more akin to embossing or debossing rather than printing with ink.

Here are some considerations if you want to try using a rosin press for embossing on leather:

-

Leather Type:

- Different types of leather may respond differently to heat and pressure. It’s advisable to test the process on a small, inconspicuous piece of leather before attempting a larger project.

-

Temperature and Pressure Control:

- Many rosin presses allow for temperature and pressure adjustments. Experiment with different settings to find the optimal combination for embossing leather without causing damage.

-

Design and Material:

- Designs for embossing should be well-suited for the type of leather you are working with. Intricate or detailed designs might require different considerations.

-

Protection:

- Use protective measures such as a Teflon sheet or parchment paper between the leather and the press to prevent sticking and ensure a smoother release.

-

Safety Precautions:

- Be mindful of safety considerations, such as avoiding excessive temperatures that could damage the leather or release harmful fumes.

It’s important to note that a rosin press is not the most conventional tool for leather embossing, and there are dedicated embossing machines designed for this purpose. However, if you’re interested in experimenting with what you have, the rosin press could potentially be adapted for small-scale leather embossing projects with careful attention to the variables mentioned above. Always prioritize safety and test on a small scale before committing to larger projects.