Heat Press Direct

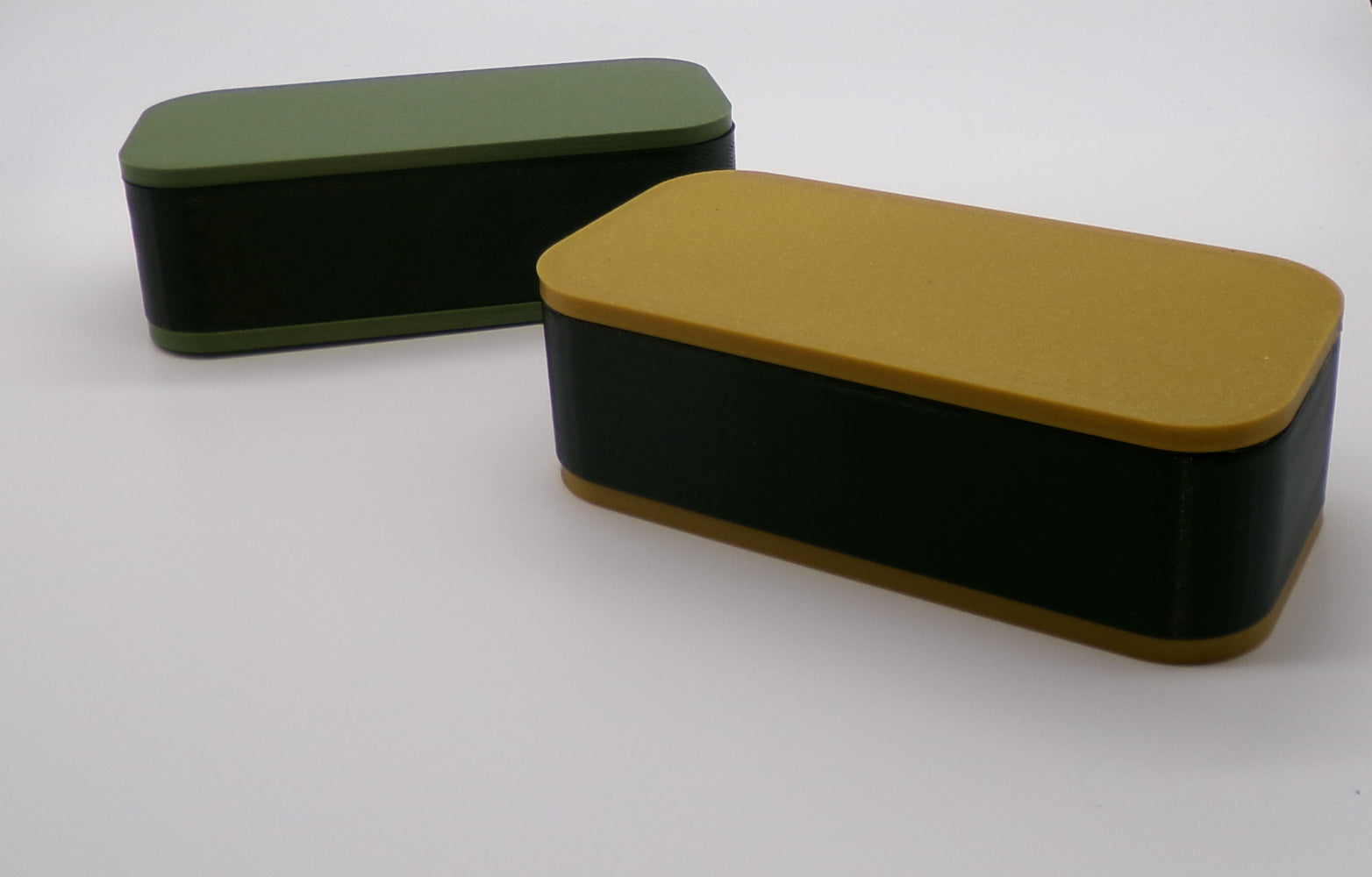

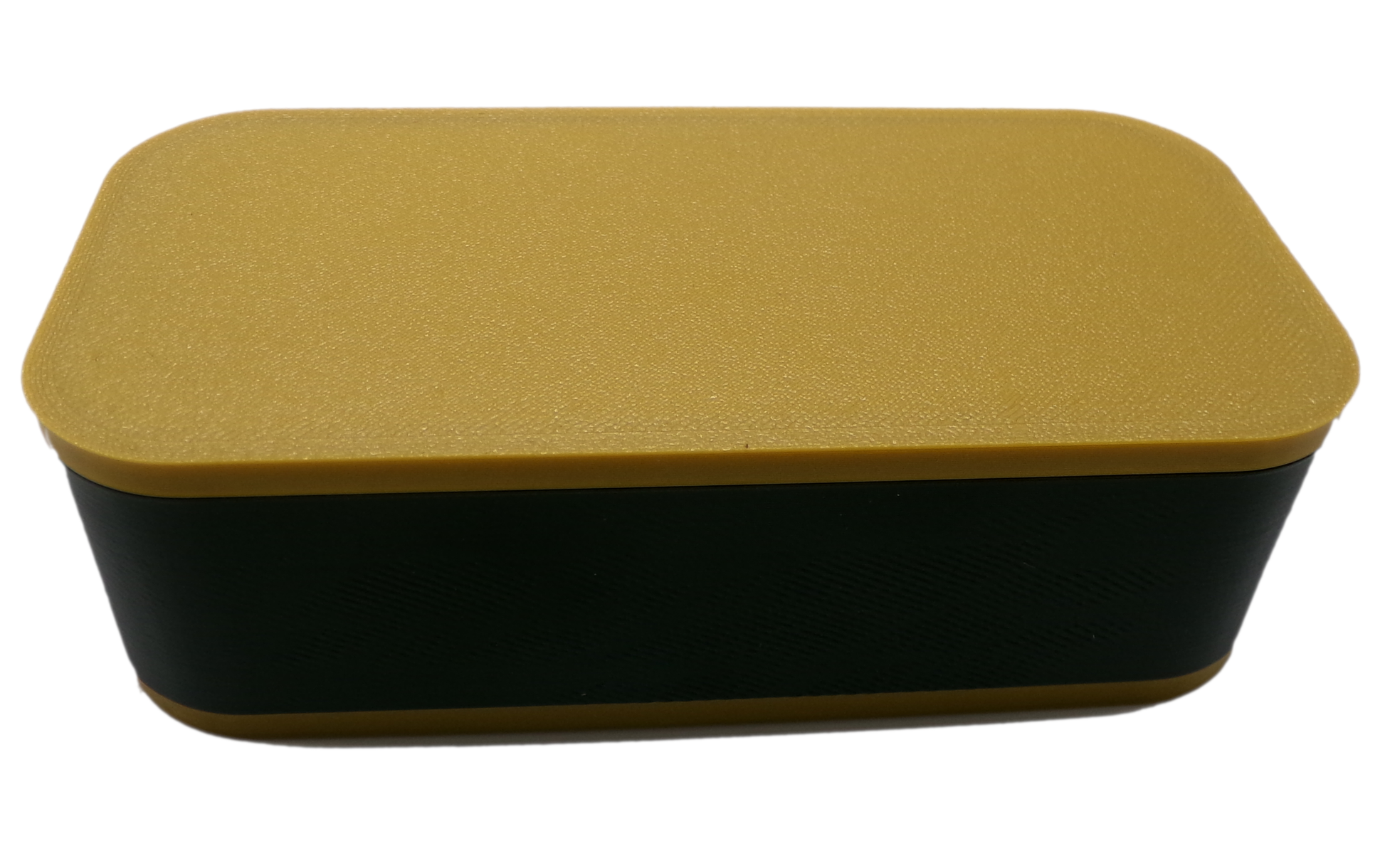

Moule de pré-pressage – augmentez vos rendements en créant une brique/galette

Moule de pré-pressage – augmentez vos rendements en créant une brique/galette

🖤 Le Black Friday commence MAINTENANT ! Évitez la cohue et économisez 10 % aujourd’hui avec le code Save10now

Impossible de charger la disponibilité du retrait

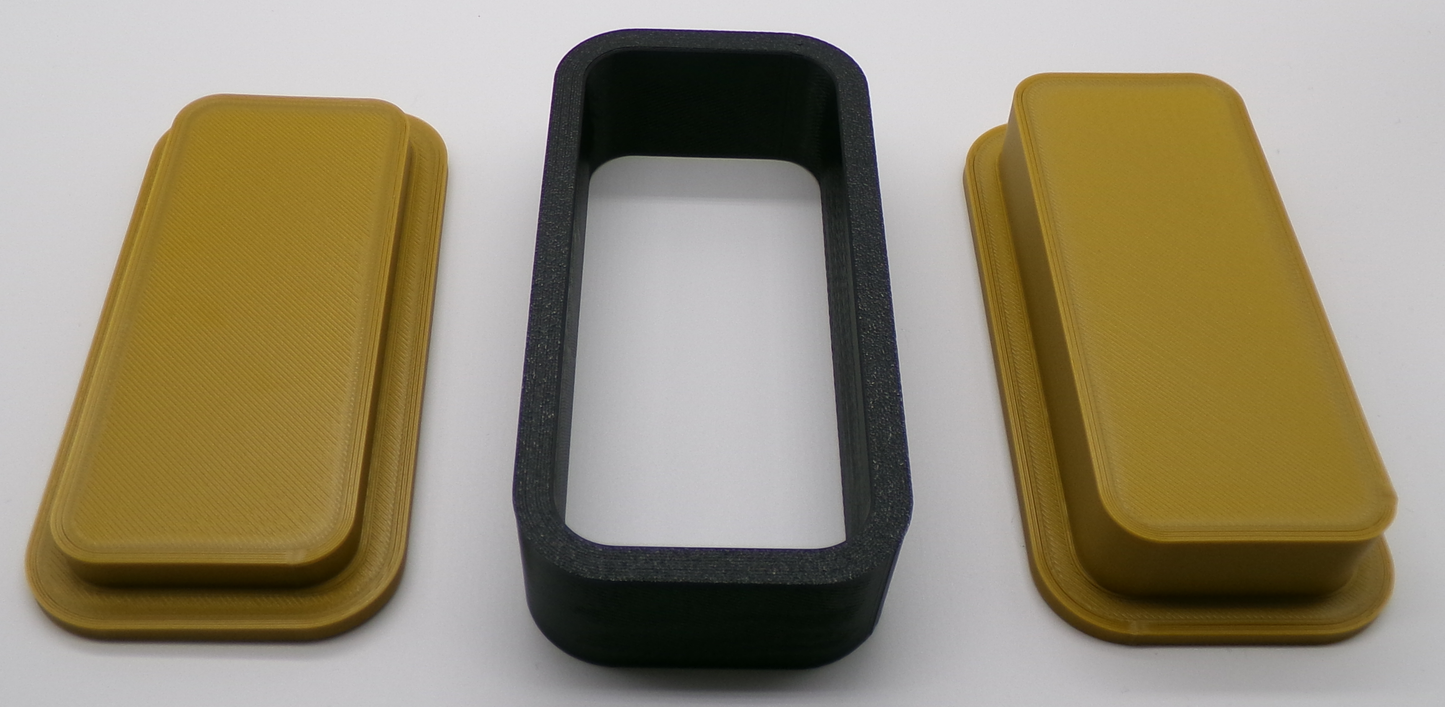

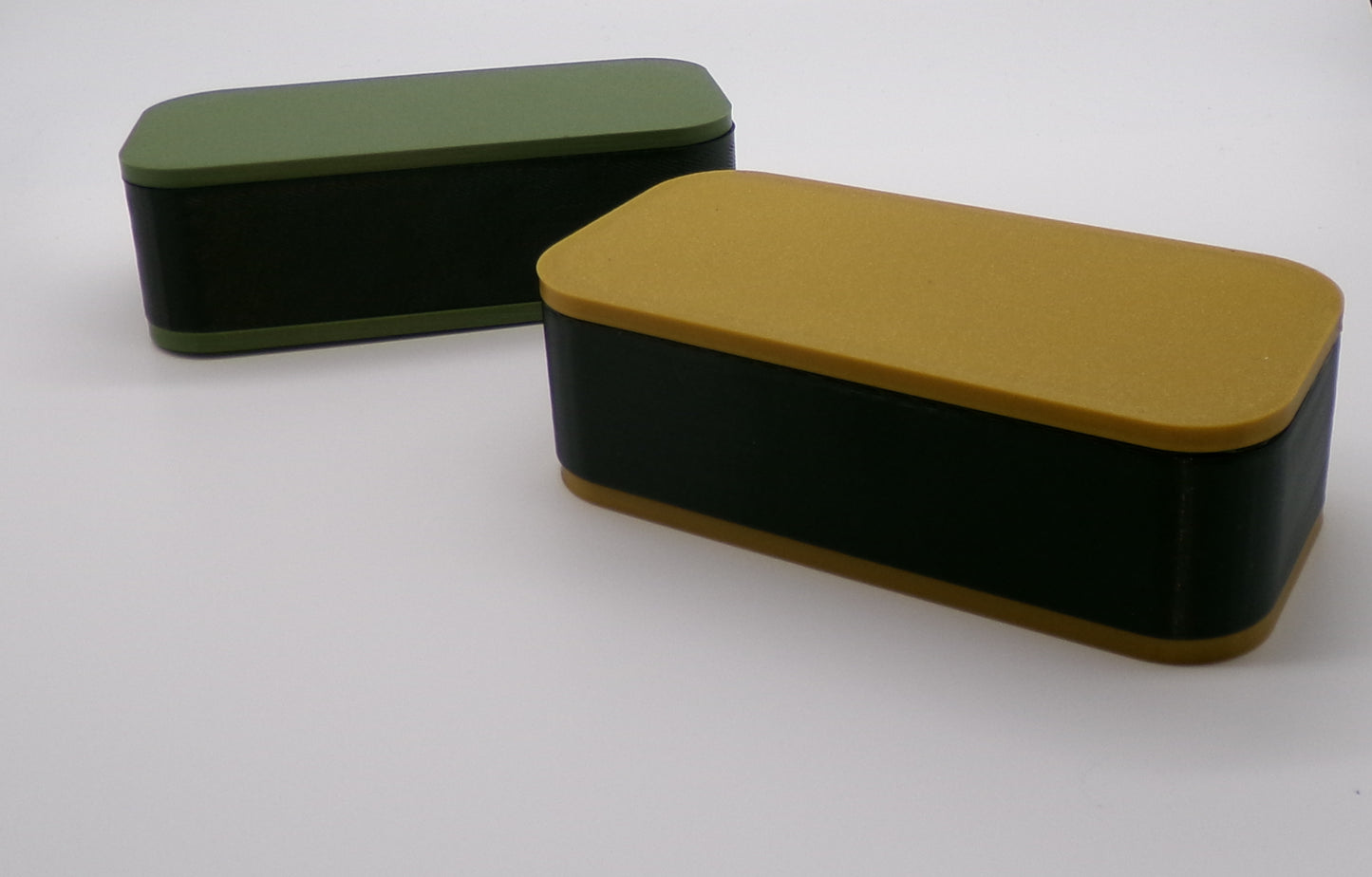

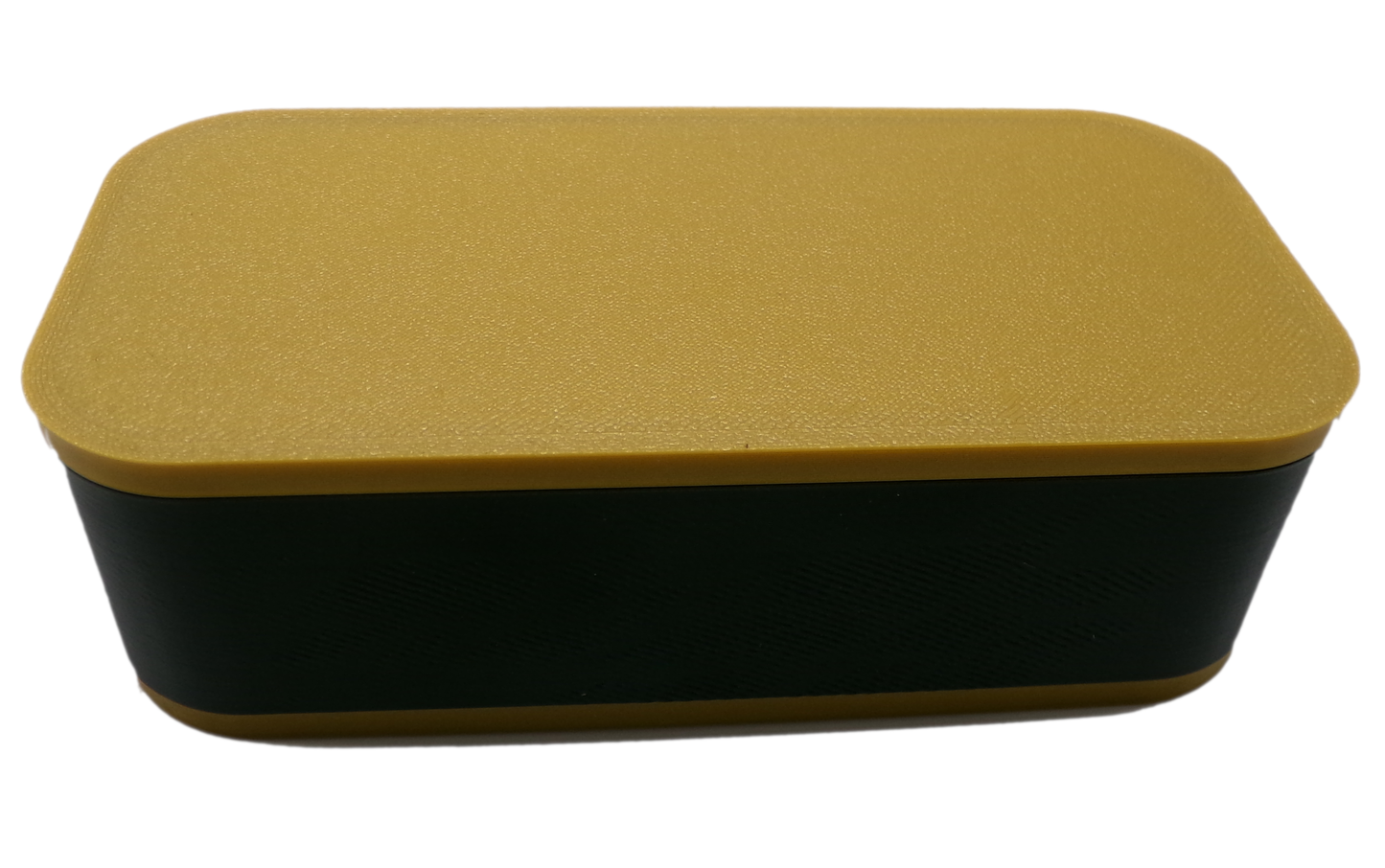

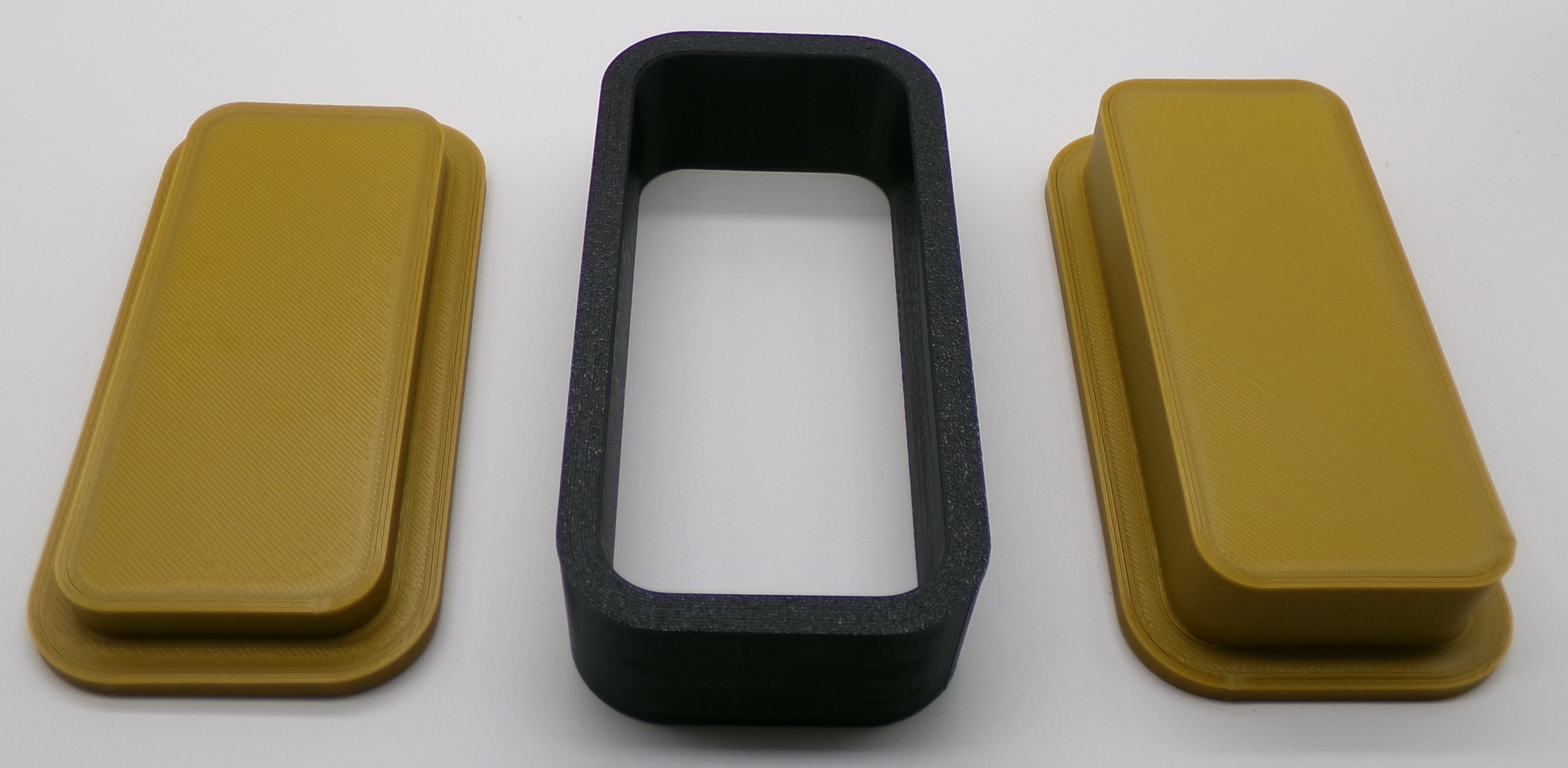

Ce moule de pré‑pressage rectangulaire est conçu pour compacter les fleurs en vrac en briques ou galets nets. Le pré‑pressage augmente les rendements, fait gagner du temps et réduit les risques d’éclatement des sacs filtres lors du pressage à chaud !

Caractéristiques principales :

Moule de pré-pressage en ABS imprimé en 3D, fabriqué au Royaume-Uni | 4,25" x 1,75" | Durable & de précision

Améliorez votre configuration de pré‑pressage avec ce moule imprimé en 3D de haute qualité, fabriqué au Royaume‑Uni et conçu pour des performances constantes et une durabilité à long terme. Réalisé en plastique ABS robuste, ce moule est idéal pour ceux qui recherchent précision et qualité dans leur processus de pressage.

Caractéristiques du produit :

- ABS de haute qualité : Fabriqué en plastique ABS solide et durable, garantissant longévité et fiabilité à chaque utilisation.

- Fabriqué au Royaume‑Uni : Fièrement imprimé en 3D au Royaume‑Uni, ce moule respecte des normes de qualité strictes et vous offre un produit supérieur sans les longs délais d’expédition ni l’impact environnemental liés à une production à l’étranger.

- Dimensions idéales : Avec des dimensions internes de 4,25 pouces par 1,75 pouce, ce moule est parfait pour obtenir des résultats uniformes et réguliers lors de vos opérations de pré-pressage.

- Ingénierie de précision : Conçu avec une attention méticuleuse aux détails pour garantir un ajustement parfait et un fonctionnement fluide à chaque utilisation.

- Choix écoresponsable : soutenez la production locale et réduisez votre empreinte carbone en choisissant un produit fabriqué au plus près de chez vous.

Pourquoi l’ABS (Acrylonitrile Butadiène Styrène) ?

Le plastique ABS est exempt de plastifiants nocifs et de métaux lourds, ce qui en fait un matériau sûr pour les jouets et autres produits destinés aux enfants. Cette caractéristique non toxique répond à la demande croissante de matériaux sûrs et adaptés aux enfants. En fait, l’ABS est utilisé dans les célèbres briques LEGO, ce qui rassure les parents et les personnes en charge.

Pourquoi acheter chez nous ?

Ce moule de pré-pressage n’est pas un simple outil de plus ; c’est un ajout fiable à votre procédé, offrant une qualité et une précision de fabrication britannique sur lesquelles vous pouvez compter. Idéal pour un usage professionnel comme personnel, c’est un incontournable pour quiconque souhaite obtenir des résultats constants et de haute qualité.

Commandez la vôtre dès aujourd’hui et découvrez la différence de la qualité et du savoir‑faire britanniques !

Pourquoi choisir notre moule de pré-pressage ?

En choisissant notre moule de pré‑pressage fabriqué au Royaume‑Uni, vous investissez non seulement dans un produit supérieur, mais vous soutenez également des pratiques durables et les industries locales. Nos moules offrent une solution fiable, sûre et économique pour vos besoins de pré‑pressage.

L’utilisation d’un moule de pré‑pressage prépare votre matière végétale au processus de pressage de rosin. Le rosin est une méthode d’extraction sans solvant qui utilise la chaleur et la pression pour extraire les huiles essentielles de diverses plantes. Un moule de pré‑pressage aide à façonner et compacter votre matière avant son passage dans la presse à rosin. Voici un guide étape par étape sur la façon d’utiliser un moule de pré‑pressage pour rosin :

Matériel nécessaire :

- Moule de pré‑pressage

- Matière végétale

- Papier sulfurisé

- Presse à rosin

- Sachets filtrants micron (en option)

Procédure :

1. Préparez votre matière végétale

- Si vous utilisez des fleurs d’herbe, émiettez‑les en petits morceaux, passez‑les au grinder.

- Si vous utilisez autre chose, assurez‑vous d’obtenir une texture homogène.

2. Charger le moule de pré-pressage

- Ouvrez le moule de pré-pressage et placez une feuille de papier sulfurisé d’un côté.

- Ajoutez la quantité souhaitée de matière sur le papier sulfurisé, en veillant à ce qu’elle soit bien centrée dans le moule.

3. Fermer le moule

- Rabattez l’autre moitié du moule sur la matière végétale, en la coinçant entre les feuilles de papier sulfurisé.

4. Presser et compacter

- Appliquez une pression sur le moule afin de compresser la matière végétale. Cette étape permet de créer une galette plus homogène et compacte, ce qui peut améliorer l’efficacité de l’extraction du rosin.

5. Retirer la galette

- Ouvrez le moule et retirez délicatement la galette comprimée de matière végétale. Le papier sulfurisé doit permettre de la sortir facilement sans abîmer la matière.

6. Optionnel : utiliser des sachets filtrants micron

- Si vous souhaitez encore affiner votre rosin et éviter que la matière végétale ne contamine l’extrait, vous pouvez placer la galette compressée dans un sachet filtrant micron avant de la mettre dans la presse à rosin.

7. Préchauffez votre presse à rosin

- Réglez votre presse à rosin à la température souhaitée. La température optimale peut varier selon des facteurs tels que la variété et la texture de votre matière de départ.

8. Placer la galette dans la presse à rosin

- Positionnez la galette compressée au centre d’un morceau de papier sulfurisé et placez‑la entre les plaques chauffées de la presse à rosin.

9. Pressez le rosin

- Fermez la presse à rosin et appliquez la pression. La chaleur et la pression vont extraire les huiles essentielles de la matière végétale pour produire votre rosin.

10. Collecter le rosin

- Ouvrez la presse, retirez délicatement la galette et récupérez le rosin sur le papier sulfurisé.

Avertissements :

Il n’est pas nécessaire de chauffer un moule de pré‑pressage pour former une galette : seule la pression est requise.

Livraison & retours

Livraison & retours

Procédure de retour simple

Si vous n’êtes pas satisfait de votre achat, vous disposez de 30 jours pour nous en informer et retourner votre presse pour un remboursement intégral !

Nous expédions dans le monde entier depuis le Royaume‑Uni avec Royal Mail & Parcelforce pour un service rapide et fiable.

Les commandes passées avant 15 h sont expédiées le jour même avec un suivi complet fourni.

Heat Press Direct a mis en place des systèmes pour que vous sachiez exactement où en est votre commande, et vous serez averti par voie électronique à chaque étape.

Les commandes au Royaume‑Uni sont envoyées en livraison suivie le lendemain, vous recevrez donc votre commande le jour ouvrable suivant.

Les commandes dans l’UE sont livrées en moyenne sous 3 à 4 jours ouvrables et tous les droits et taxes sont prépayés, il n’y aura donc pas de frais supplémentaires.

Si vous avez le moindre doute, n’hésitez pas à envoyer un e‑mail à hello@heatpressdirect.co.uk

Si vous n’êtes pas satisfait de votre achat, veuillez nous contacter à hello@heatpressdirect.co.uk

Garantie

Garantie

Soyez assuré que si un problème survient avec votre presse, nous vous couvrirons. Nos presses tombent rarement en panne, mais si c’est le cas, contactez‑nous à hello@heatpressdirect.co.uk

Notre garantie est de 2 ans et, si vous rencontrez un problème, nous réparerons ou vous enverrons une presse de remplacement.

Partager